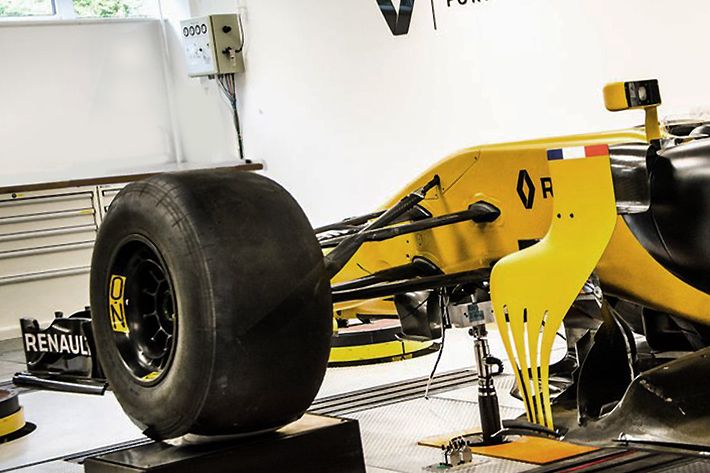

After leaving behind Renault’s simulation room and its enforced obscurity, we head towards a building radiating with light to discover another tool recently upgraded at Enstone.

As we enter, an RS17 chassis, lacking its bodywork and a power unit, sits atop a seven-post rig capable of submitting a car to a three-dimensional simulation run on any track.

Four hydraulic jacks placed under the wheels replicate bumps and camber changes while three additional – called “aeroloaders” – reproduce roll, pitch and yaw. And there’s also a mass damper right underneath where the driver sits to simulate the dynamics of the human presence.

Venezuelan engineer Rene Torcato – who has joined the ranks of Formula E since our visit to Enstone last year – elaborated on the rig’s purpose and function.

© Renault F1

A COMPLIMENTARY TOOL

“Our simulation tools need to complement each other,” he explained.

“Some things are easier to build and run on the real car, while for other things it’s easier to create a model or test on the simulator.

“The seven-post-rig is a testing facility used to improve the car’s performance through the suspension, where we are able to replicate what the car does on the track in the controlled environment of the laboratory.

“We replicate pitch, roll but also the downforce. We can assess set-up changes and look ahead to different concepts for both the current car and future designs.”

© Renault F1

On race weekends, the crews at Enstone can collect data from Friday’s running and enter the information into the rig’s computer with the purpose of trialing various set ups that take into account the track’s topography and characteristics.

“At Enstone, we think it is important to test the real vehicle as much as we can to help optimise the car when at the track,” Rene added.

“We use our seven-post rig to repeat the profile of different tracks to see how to set up the car and what compromises to make between grip and aero levels, depending on the specificities of each track.”

“For example, Monaco is grip dependent, but Monza is more aero dependent. We can make a set-up change and evaluate this change on the first five tracks of the season, for example.

“This helps us to see how that change affects the car’s response to specific corners under specific conditions at each track independently.

“We have other cars that we can use for development work (to try new concepts, etc.). We may also use last year’s car to try a new part, because we can see the effect of this new component on the performance, whereas with this year car.”

'

'