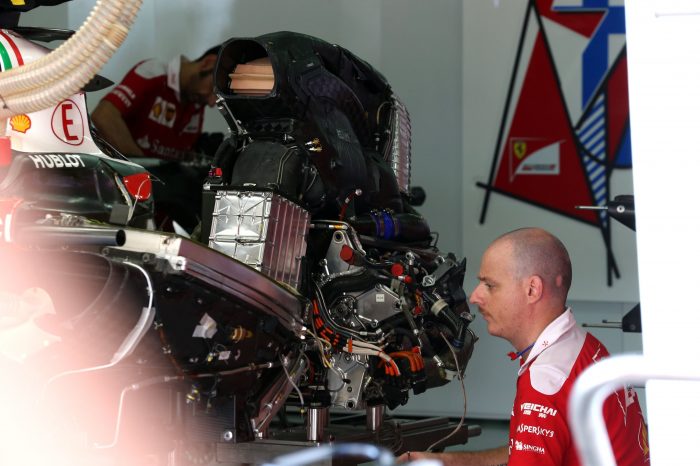

In its bid to optimize engine design, and more specifically in the combustion chamber area, Ferrari's engineers are considering using Additive Manufacturing technology, or 3-D printing as it's called in the mainstream world.

The technology, which is slowly but surely enjoying a widespread industrial adoption, involves adding layer-upon-layer of material, whether the material is plastic, metal or concrete to form a component.

Indeed, McLaren announced earlier this week a partnership with 3-D company Stratasys for printing solutions and cutting-edge materials for visual and functional prototyping, production tooling including composite tooling, and customised production parts.

Ferrari's 2017 engine design is rumored to have very little in common with its previous iteration, with engineers having specifically focused on combustion, with substantial increases in both pressure and temperature which could pose a threat to reliability.

As it looks to optimize its components, both in terms of design and material, Ferrari is seeking to innovate with Maranello engineers assessing 3-D printing as a possible means to create complex forms which cannot be achieved using traditional casting and machining processes.

But the innovative technology also allows the use of steel allows instead of aluminum allows, with the former offering better resistance to pressure and temperature while no longer presenting a weight disadvantage compared to aluminum alloys, thanks to a specific honeycomb form achieved in the manufacturing process by 3-D priniting.

Scuderia technical director Mattia Binotto would probably be the first to admit that Ferrari is certainly not alone to research the virtues of Additive Manufacturing, but the Italian engineer is hopeful of introducing its positive results as soon as possible.

GALLERY: F1 drivers' wives and girlfriends

Keep up to date with all the F1 news via Facebook and Twitter