McLaren technical director James Key says the integration of Mercedes' power unit with the team's MCL35 chassis left his engineering department with multiple challenges and complexities to solve.

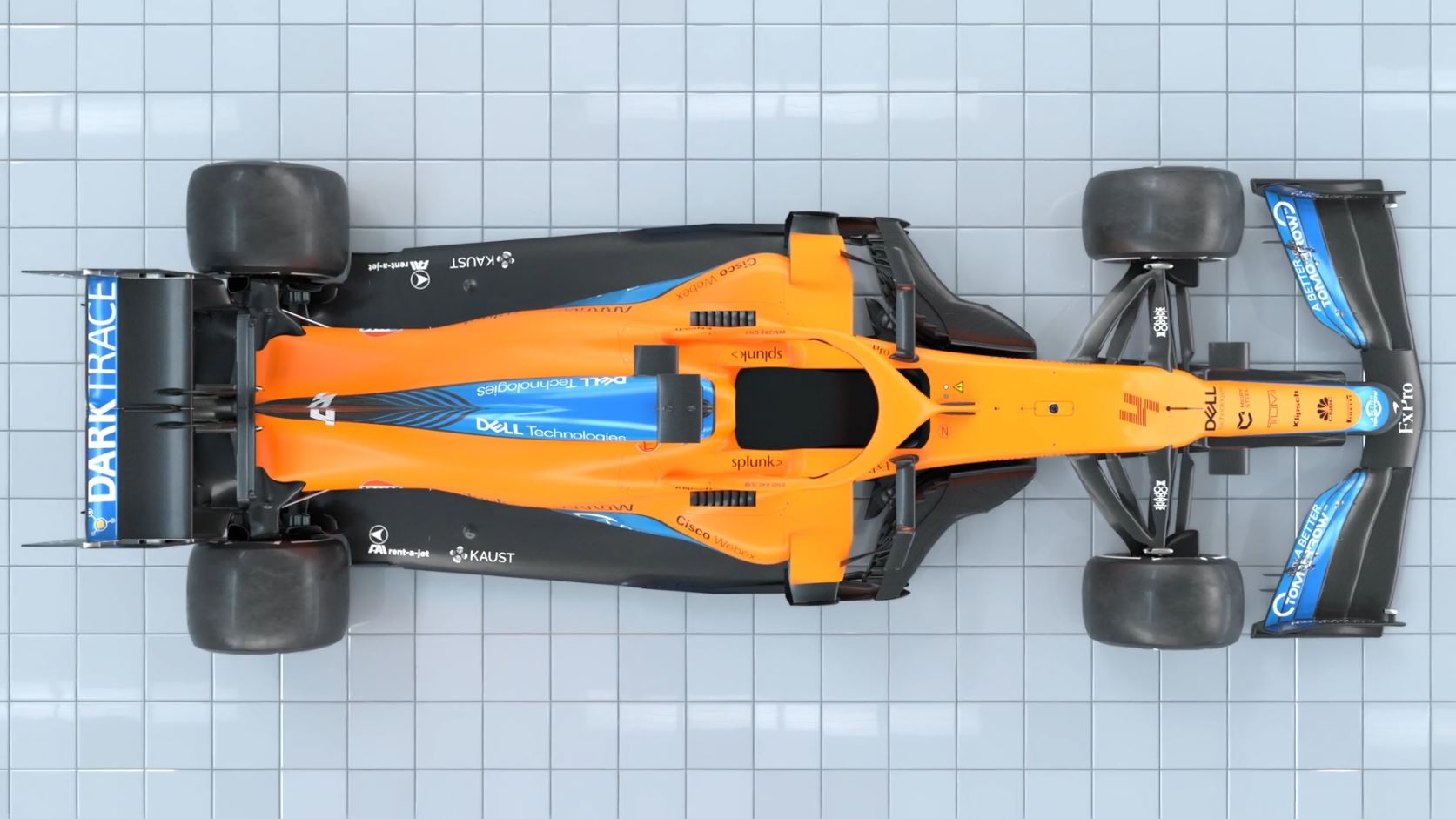

Formula 1's cost-saving regulations forced on teams a mandatory carry-over of last year's chassis. But as the only outfit on the grid undergoing a power unit change, McLaren's undertaking was certainly more complicated than the adaptation process faced by its rivals.

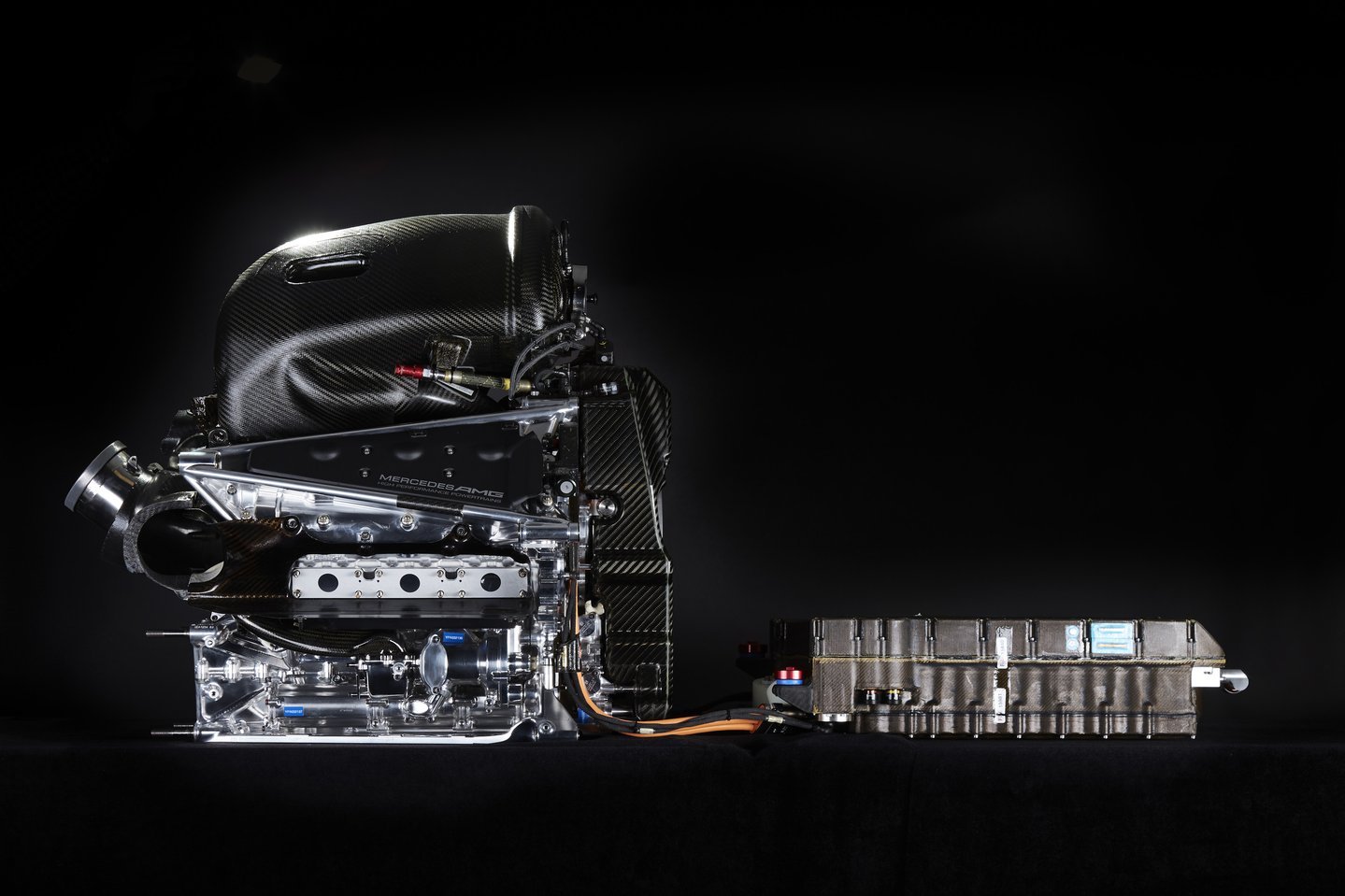

Such was the extent of the changes impacting the rear end of McLaren's MCL35 that it was forced to spend both its development tokens on the transformation of its chassis to accommodate the car's new unit, a conversion that included changes to major elements such as the cooling layout, gearbox, energy store and electrical system.

"A lot of the components involved in the engine installation were frozen actually at the beginning of last season so that obviously put us in a bit of a spot but of course there were allowances for that," Key explained.

"It meant we had to undertake what is a very different installation. Every installation is really quite different, there’s no one solution to how these power units are laid out, all the sizing of the various components can affect the car’s architecture.

"So, what we needed to try and do was respect the homologation process by not changing things that didn’t need to change in line with installing the engine. But clearly, making the changes we needed to with homologated parts.

"So that allowed us to change the chassis, which of course has to change with a new engine and energy store, and aspects of the gearbox for packaging purposes but after that, it’s all identical to last year. The electrical system is completely different, of course, the cooling system - well that’s going to be largely homologated this year. The cooling systems are totally different as well.

"Fundamentally the architecture of the car is quite different but the homologated areas of the car which we needed to stick to are areas unaffected as possible. Amongst all the other challenges of trying to get this done, it added an extra dimension which probably led to a slightly sub-optimal approach compared to what you do if you’re completely free but I don’t think it was that much of a compromise."

While Mercedes' power unit remains the undisputable 'industry standard' in terms of performance and reliability, packaging the unit within the MCL35's preset "homologated environment" was an obviously crucial undertaking, but one that was fortunately helped by the engine's "tidy" architecture according to Key.

"I think on the installation side there are pros and cons with the different architectures we have," added the McLaren engineer.

"You typically have the front-mounted compressor versus the sort of compressor-turbo on the rear – that’s the most significant change in terms of layout.

"I think the Mercedes installation is certainly extremely tidy, you can see how much attention into the detail has gone into it, so straightforward to pack, in that respect and that has given us a few plus points.

- Read also: McLaren MCL35M hits the track at Silverstone

"Equally there are other demands in a few areas, that we had to adjust, so I guess there’s no one right answer to that. I think the different architectures have pros and cons on different sides but I think what has become clear is that the Mercedes installation is very good to work on.

"We had to install this engine in the homologated environment, and I think working with the Mercedes colleagues, with what they have supplied us, it has been relatively easy to try to shoehorn this engine into the homologated car."

As McLaren's engineers interfaced in the past months with their Mercedes colleagues at Brixworth, Key says the association has been a positive and straightforward affair, perhaps helped in part by the two partners' successful past together.

Gallery: The beautiful wives and girlfriends of F1 drivers

Keep up to date with all the F1 news via Facebook and Twitter